Reference TD-IT-1017

TECHNOLOGY DESCRIPTION

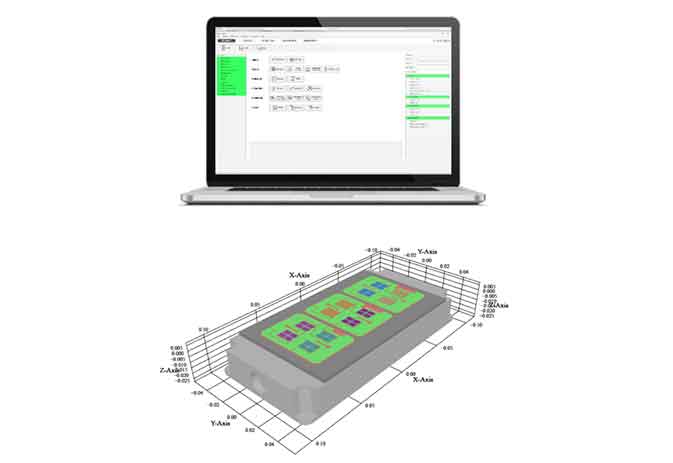

The Virtual Thermal Sensing (VTS) technology allows real-time, sensorless estimation of internal temperatures in electromechanical systems such as motors, inverters, and power modules. By using multiphysics models, reduced-order models, and data-driven calibration, VTS reconstructs thermal conditions at critical hot spots without additional sensors or hardware redesign. The technology runs on embedded ECUs, supports a variety of processors and operating systems, and integrates directly with existing control systems. Applications span from automotive to aerospace and industrial automation especially where high power density and thermal reliability are required. The VTS platform is the result of over 5 years of R&D and has already been validated in Tier-1 automotive use cases, making it robust and ready for adaptation across domains including space systems with minimal mass and sensing redundancy requirements.

• Sensorless estimation of rotor, winding, and junction temperatures

• Seamless integration into ECU control loops

• Real-time thermal control and smart derating strategies

APPLICATION AREAS

Electric powertrains, Automotive, Aerospace, Renewable energy, Industrial automation

TECHNOLOGY READINESS LEVEL

9 (non-space)

COUNTRY OF ORIGIN

Italy

LATEST UPDATE

2024